Energy Consumption vs. Performance: Key Efficiency Metrics in Packaging Machinery

In today’s highly competitive industrial landscape, sustainability, cost management, and operational speed have become critical parameters that must be optimized simultaneously. The same applies to the machines operating on packaging lines: the balance between energy consumption and performance directly affects both operating costs and overall production efficiency. For this reason, modern manufacturing facilities now prioritize not only high-speed machines but also systems that are energy-efficient and fully optimized.

So, how is efficiency measured in packaging machinery? Are energy consumption and performance truly opposing concepts, or can they be optimized together through the right engineering approach? In this article, we examine the key technical metrics that define efficiency in packaging machines.

Energy Consumption: Actual Energy Factors in Vertical Packaging and Case Packing Systems

The primary factors influencing energy consumption in vertical packaging (VFFS) and case packing machinery include:

1. Servo Systems and Motor Efficiency

In modern VFFS and case packing machines, the largest share of energy consumption comes from servo motors and motion groups.

-

High-efficiency IE3/IE4 motors

-

Dynamic energy regeneration in servo drives

-

Optimized torque management

significantly reduce overall energy usage.

2. Vacuum and Compressed Air Usage

Vertical packaging machines do not involve direct thermal processes; however, pneumatic components, vacuum systems, and jaw movements play a major role in energy consumption. Machines equipped with servo-driven sealing jaws instead of pneumatics can achieve up to 20% energy savings.

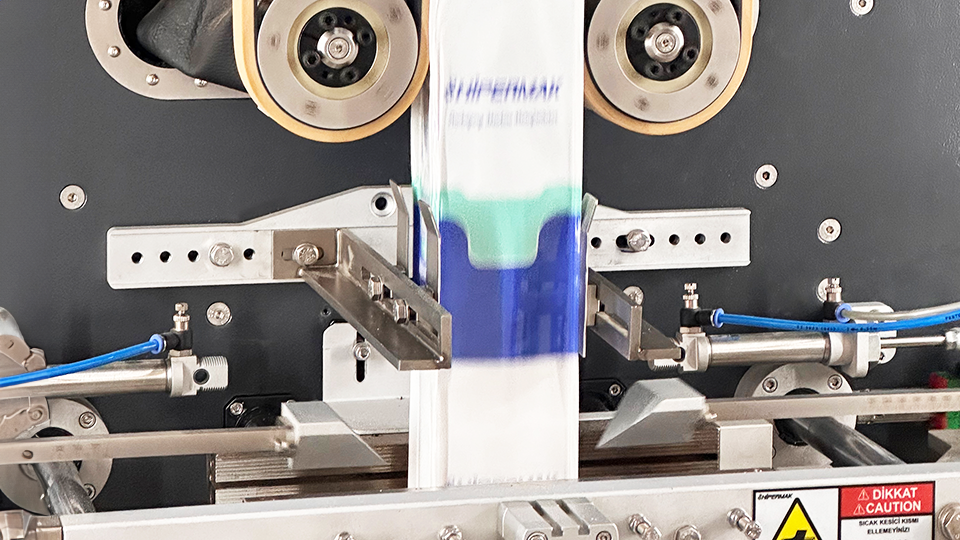

3. Film Feeding Mechanisms

The film pulling group (belts, servo-driven nip rollers, etc.) operates continuously and directly impacts line speed.

Optimized film tension and low-friction surfaces help prevent unnecessary energy losses.

4. Control Software and Standby Mode

Automatically switching to a low-power mode when the machine is idle provides significant energy savings—especially in multi-shift food production facilities. Today, PLC software is a key component of energy management.

Performance: How Real Efficiency Is Measured in Vertical Packaging Machines

Performance is not limited to PPM (packs per minute). In the food industry, performance encompasses a broader set of criteria.

1. Cycle Time and Filling Dynamics

The flow characteristics of granular, powdered, or free-flowing products directly affect cycle time.

Key performance parameters include:

-

Fast-response servo sealing jaws

-

Precise synchronization of linear or auger filling systems

2. OEE (Overall Equipment Effectiveness)

Within Hipermak’s production approach, OEE is a core metric:

-

Availability: Minimizing unplanned downtime

-

Performance: Operating as close as possible to theoretical speed

-

Quality: Reducing sealing defects, incorrect dosages, or filling errors

A machine with low energy consumption but poor OEE cannot be considered truly efficient.

3. Packaging Material Compatibility

Different film structures such as PE, PP, laminated films, high-barrier materials, or compostable films affect not the sealing temperature profile (since Hipermak machines involve limited thermal processing), but:

-

Tensile strength

-

Friction

-

Pulling resistance

These factors directly influence film feeding energy and machine speed.

4. Automation Level and Sensor Technology

-

High-precision load cells

-

Film alignment and position sensors

-

Jaw-position encoders

-

IoT-based data collection systems

These technologies enhance performance while simultaneously minimizing unnecessary energy consumption.

Advanced Approaches That Improve Both Energy and Performance

1. Data-Driven Energy Management

Real-time monitoring of energy and performance provides insight into questions such as:

“At which point in the line is energy consumption increasing?”

2. Recipe-Based Automatic Adjustments

When switching products, automated optimization of jaw pressure, film tension, and filling parameters reduces energy loss and stabilizes line speed.

3. Servo-Based Motion Optimization

In case packing systems, optimizing the speed-torque curves of servo robotic arms enhances performance while balancing energy load.

4. Integrated Error Prevention Systems

Early detection of issues such as incorrect filling, product jams, or film misalignment minimizes unnecessary stoppages and wasted energy.

Energy and Performance: Two Variables in the Same Equation

In food-industry vertical packaging and case packing machinery, energy consumption and performance are not opposing concepts. With proper engineering, these two factors complement each other.

As reflected in Hipermak’s machine design philosophy:

-

High-efficiency servo technology

-

Minimal pneumatic usage

-

Intelligent PLC control

-

Optimized film and filling management

-

Data-driven performance monitoring

all contribute to reducing energy consumption while maximizing production speed and quality.

Ultimately, packaging systems that deliver the highest output with the lowest energy input will define the future standards of sustainability and competitiveness.