The Art of Pasta Packaging: Meet the High Capacity of Hipermak Packaging Machines!

Pasta, one of the world’s most beloved comfort foods, comes in a myriad of shapes and sizes, each designed to capture and hold the perfect amount of sauce. As pasta enthusiasts, we often marvel at the artistry behind crafting the ideal pasta shape. However, the journey from the production line to your kitchen involves a crucial step that often goes unnoticed – packaging.

Packaging short-cut pasta might seem like a straightforward task, but it requires a delicate balance of precision, efficiency, and technology. In this article, we will unravel the technical intricacies involved in short-cut pasta packaging, exploring the key considerations and highlighting the cutting-edge capabilities of Hipermak packaging machines, which can achieve a remarkable capacity of up to 110 packages per minute.

- Pasta Shape Matters: Designing the Perfect Package

Short-cut pasta, with its diverse shapes, demands packaging that not only preserves its integrity but also enhances its visual appeal on the shelves. Different pasta shapes have unique requirements, and packaging must accommodate these variations.

The packaging process begins with carefully measured portions of pasta, ensuring consistency in each package. The design of the packaging must allow for easy filling and sealing, keeping the pasta secure while preventing breakage or damage during transportation.

- Material Selection: Balancing Durability and Sustainability

Selecting the right packaging material is a critical aspect of short-cut pasta packaging. The material must provide a protective barrier against external elements, such as moisture and air, to maintain the pasta’s freshness. Additionally, in an era where sustainability is paramount, packaging solutions must strike a balance between durability and environmental impact.

Innovative materials, such as eco-friendly films and recyclable packaging, are gaining prominence in the industry. Hipermak packaging machines are equipped to handle a variety of materials, adapting to the evolving needs of environmentally conscious consumers.

- Precision in Sealing: The Seal of Freshness

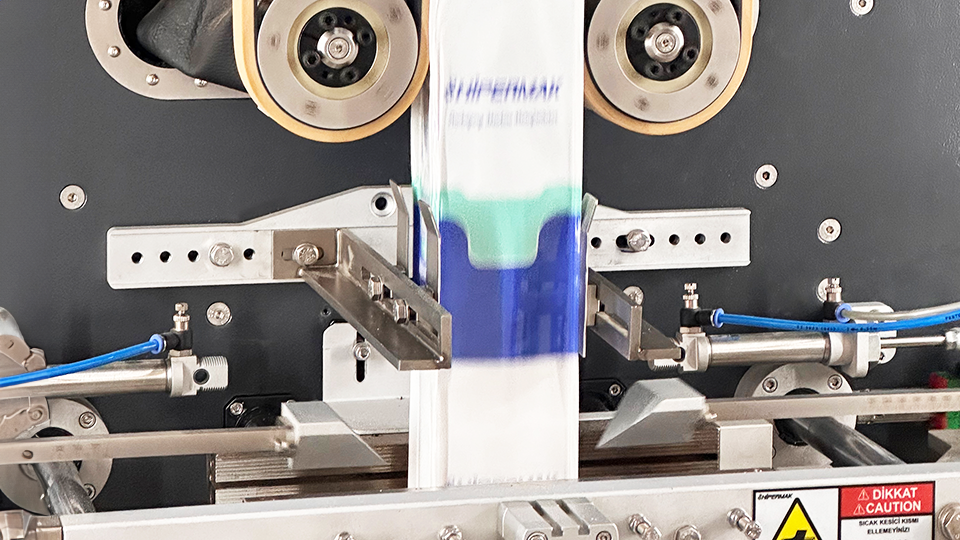

The seal on a pasta package is not just a closure; it’s a promise of freshness. Achieving a secure and airtight seal is crucial to preserving the pasta’s quality and taste. Hipermak packaging machines are engineered with precision sealing mechanisms, ensuring that each package maintains its integrity from the manufacturing line to your dinner table.

- Automation and Efficiency: Hipermak’s 110 Packages per Minute

In the fast-paced world of pasta production, efficiency is key. Hipermak packaging machines stand out with their impressive capacity of up to 110 packages per minute. This level of automation not only accelerates the packaging process but also minimizes the margin of error, guaranteeing a consistent and high-quality end product.

- Adaptability and Customization: Meeting Diverse Market Demands

Short-cut pasta comes in various shapes and sizes, and market trends are ever-changing. Hipermak packaging machines are designed with adaptability in mind. They can be easily configured to accommodate different pasta shapes and sizes, allowing manufacturers to swiftly respond to market demands and maintain a competitive edge.

In conclusion, the artistry of short-cut pasta packaging lies in the meticulous fusion of technology, precision, and adaptability. As we savor our favorite pasta dishes, it’s worth acknowledging the behind-the-scenes magic that ensures the pasta reaches our plates in perfect condition. With Hipermak packaging machines leading the way, the future of short-cut pasta packaging looks not only efficient but also environmentally conscious.

Click for detailed information about the intricacies of pasta packaging!

We are here to improve your pasta packaging processes and strengthen your business. For detailed information, you can fill out the information request form on our website, send an e-mail to [email protected] or call us at +90 (232) 461 42 02.