How Hipermak Packaging Machines Contribute to Your Production Efficiency?

In today’s fast-paced and highly competitive manufacturing environment, improving production efficiency is essential for businesses to achieve sustainable success. The packaging line is one of the most critical stages of the production chain. At this point, Hipermak Packaging Machines helps optimize your processes with innovative solutions and advanced technology. So, how exactly do Hipermak machines enhance your production efficiency? Here are the key details:

1. High-Speed and Uninterrupted Operation

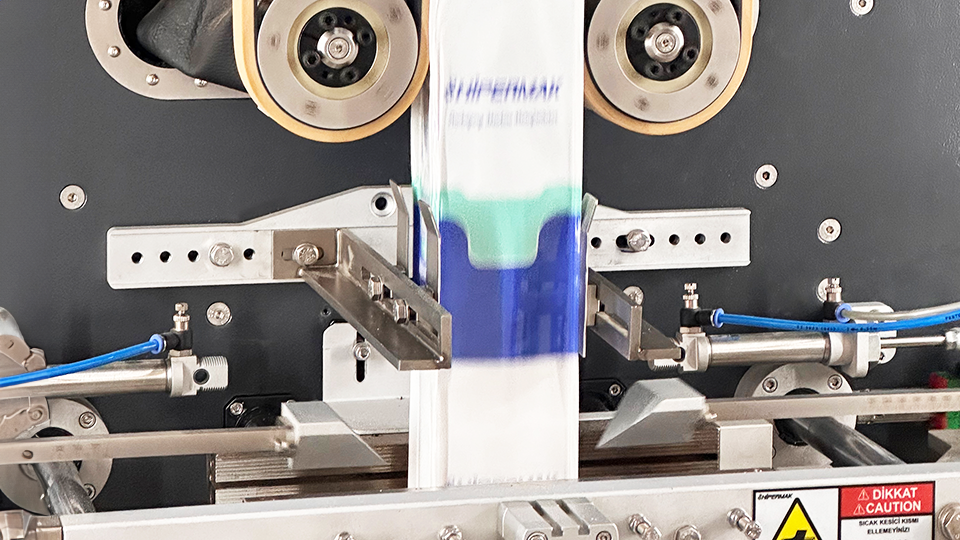

Hipermak machines are capable of performing hundreds of packaging operations per hour. With high-speed filling and sealing systems, your production line operates with minimal downtime, maximizing efficiency. Additionally:

- Continuous production with automatic film change systems,

- Error detection with smart sensors and automatic stop/start,

- Advanced servo motor technology that boosts hourly production capacity.

- Cost Savings Through Energy Efficiency

Energy consumption directly impacts production costs. Hipermak machines create an eco-friendly production environment with low energy consumption. This not only reduces your carbon footprint but also lowers your electricity expenses.

- Energy-efficient PLC-driven motors and drive systems,

- Minimal energy consumption in standby mode,

- Intelligent energy management in heaters and control systems.

- Minimal Errors, Maximum Product Quality

Even minor errors in packaging can negatively affect product quality and brand reputation. Hipermak machines standardize packaging quality with highly sensitive weighing and filling systems.

- Reduces waste with precise weight control,

- Preserves product freshness with automatic air extraction and vacuum systems,

- Ensures consistent filling and sealing for every package.

- Adaptability with Modular and Flexible Design

Hipermak machines can easily adapt to various product types and packaging formats. Their modular structure offers great convenience in new product development processes.

- Quick changeover for different weights and packaging types,

- Integrated systems for labeling, coding, and MAP,

- Ergonomic design for easy cleaning and maintenance.

- User-Friendly Interface and Automation Technology

Advanced automation features reduce operator error and allow management to easily monitor and report production data in digital environments—offering a major advantage in decision-making processes.

- Touchscreen control panel,

- Real-time production data monitoring and reporting,

- Remote monitoring and control features (Industry 4.0 compatible).

Conclusion

Hipermak Packaging Machines combine speed, quality, and cost-efficiency to elevate your production performance. With its cutting-edge technology, Hipermak supports the growth of your business and helps you stay ahead of the competition. Choose the assurance of Hipermak to boost your production efficiency. Contact us to learn more.