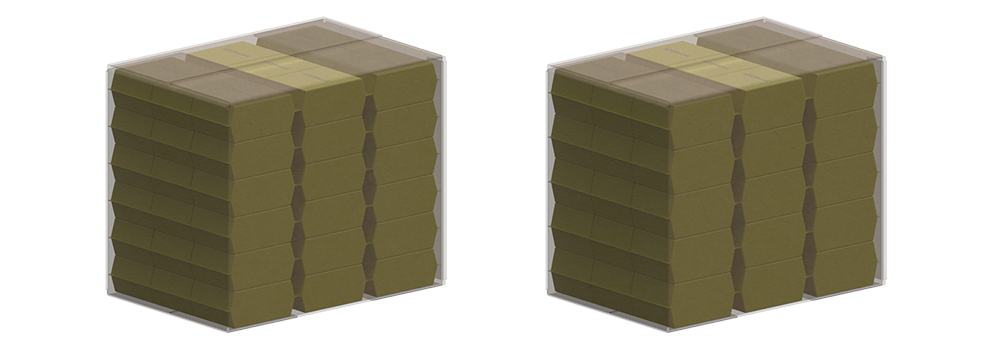

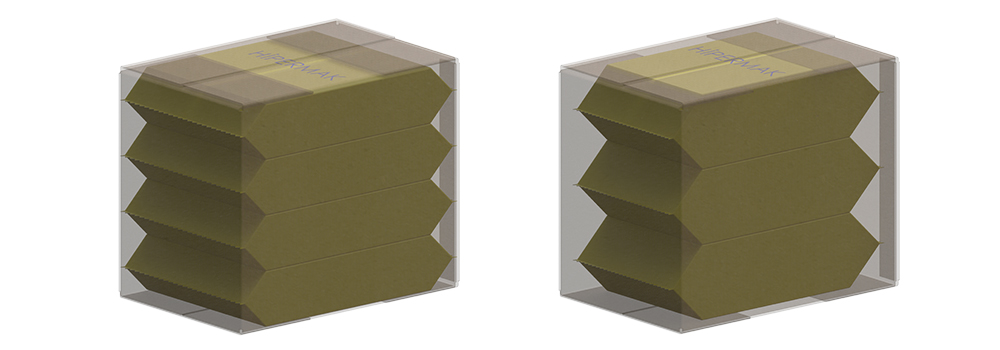

OMNIS – Top Load Case Packer

Increases existing workforce efficiency in both large and small-scale production,

Enhances productivity, saving time and costs,

Creates a seamless production process,

Reduces labor costs,

Operates efficiently at higher speeds without errors,

Prevents material waste and potential errors due to human error,

Allows automatic adjustment for box changes by defining the desired number of recipes,

More boxes can be loaded thanks to the extended box magazine, warns the operator when boxes are low, and stops automatically when boxes are finished,

Detects incomplete packages to prevent faulty boxes from being sent to customers,

Extremely robust and stable with high uptime and low operating and maintenance costs,

Touch screen control panel,

Faulty package separation system with package length control via sensors,

Hygienic design,

Automatic width adjustment according to the product,

Separate weight control unit for packages and boxes,

Places packages into the box by vibrating them during filling.

|

MAX. CAPACITY: 8-16 Box / Minute |

|

ENERGY CONSUMPTION: 10 kW |

|

AIR CONSUMOTION: 650 L / Minute 6-8 Bar |

|

BOX TYPE: FEFCO 0201 Style (American Box) |

|

BOX WIDTH: 200 – 300 mm |

|

BOX HEIGHT: 250 – 400 mm |

|

MIN. – MAX. BOX WEIGHT: 100 g – 5 kg |

|

APPROXIMATE WEIGHT: 3800 kg |

| Metal Detector |

| Package Weight Control Unit |

| Box Weight Control Unit |

| Faulty Package Separation Unit |

| Faulty Box Separation Unit |

| QR Code Printing Unit |