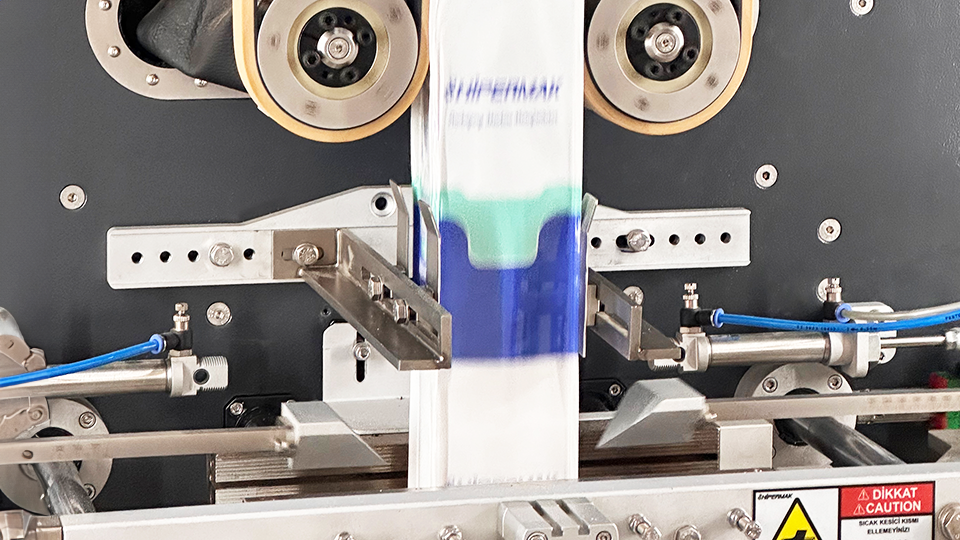

Not Just Spare Parts, But Continuity: Extend Your Machine’s Lifespan with Proactive Maintenance Planning

Packaging machines are among the most valuable components of your production line and require regular maintenance for long-term performance and efficiency. However, many companies suffer significant losses in time and cost by relying on reactive interventions after breakdowns. This is where proactive maintenance planning comes into play—an approach that ensures continuous and uninterrupted production, far beyond just replacing spare parts. So, what is proactive maintenance, and why is it important?

1. What Is Proactive Maintenance?

Proactive maintenance is a preventive approach that aims to identify potential failures before they occur. The goal is to detect wear and tear in machine components early to ensure uninterrupted production.

Key steps of proactive maintenance include:

-

Periodic inspections

-

Predictive maintenance based on sensor data

-

Pre-planning spare part requirements

-

Raising operator awareness through training

2. Prevent Unexpected Breakdowns

Machine downtime directly impacts production efficiency. An unplanned breakdown can:

-

Halt the production line

-

Delay delivery schedules

-

Increase operational costs

-

Harm brand reputation

With proactive maintenance, you can prevent these disruptions and ensure your production line runs at full capacity at all times.

3. Reduce Spare Part Costs

Emergency spare part replacements during breakdowns often result in high expenses. In contrast, pre-scheduled maintenance:

-

Allows timely ordering of parts

-

Optimizes stock management

-

Minimizes emergency spending

4. Extend Machine Lifespan, Protect Your Investment

A machine’s lifespan depends not only on how long it runs but also on how well it’s maintained. With proactive maintenance:

-

Component wear is minimized

-

Overall machine health is preserved

-

Equipment lifespan is significantly extended

-

This ultimately improves your return on investment (ROI)

5. Hipermak’s Proactive Maintenance Approach

At Hipermak, we don’t just manufacture high-tech packaging machines—we also support your team in maintaining peak machine performance for years to come.

We offer:

-

Comprehensive maintenance schedules

-

Online support and remote monitoring systems

-

A trained technical service network

-

Genuine spare parts supply

Not Just Spare Parts, But Lasting Confidence

With proactive maintenance planning, you not only extend your machine’s lifespan but also gain stability and trust in your production processes. At Hipermak, we prioritize continuity over mere part replacements—offering solutions that enhance your competitive edge.

Ready to protect your investment and maintain uninterrupted production? Contact Hipermak today and start your proactive maintenance journey!