Packaging Guide for Confectionery Manufacturers: What You Need to Know

Gummy candy production is one of the most enjoyable yet equally sensitive areas of the confectionery industry. The product’s sticky nature, combined with a wide variety of shapes and colors and continuously growing market demand, turns packaging into much more than a simple “final step.” In fact, packaging has become one of the key factors that determines the success of gummy candy production.

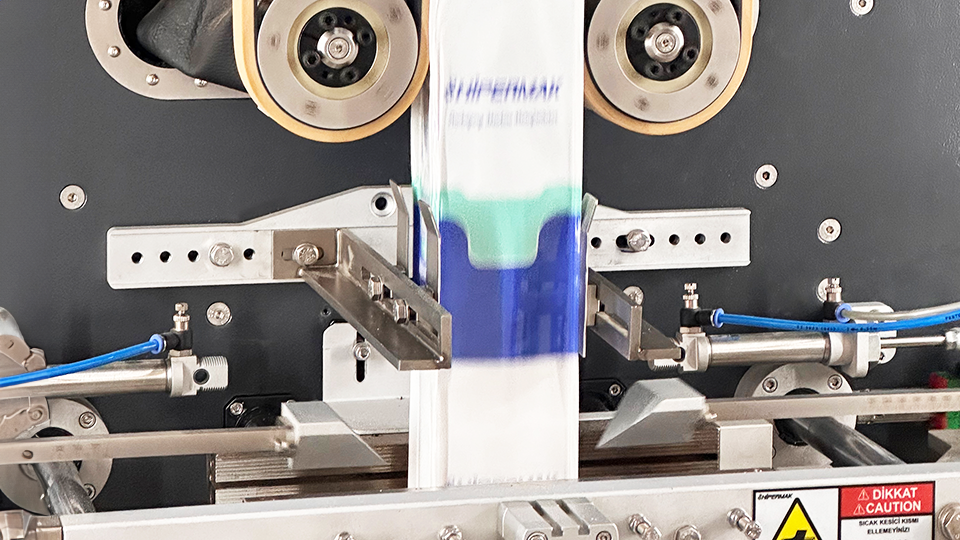

Based on our hands-on experience in the field, one thing is very clear at Hipermak:

If sustainable growth is the goal in gummy candy production, the path inevitably goes through the right packaging technology.

In this article, we cover the most important packaging considerations for gummy candy manufacturers in a clear and straightforward way.

Product Flow and Weighing: Where Everything Begins

One of the most critical aspects of gummy candy packaging is ensuring that the product moves smoothly and consistently throughout the packaging line. Due to the surface characteristics of gummy candies, certain challenges are unavoidable:

-

The product may stick to machine surfaces during flow

-

Feeding may become irregular

-

Weighing accuracy can be affected

For this reason, gummy candy packaging lines rely heavily on:

-

Product-specific vibration systems

-

Properly designed hoppers and chute structures

-

High-precision multihead weighers

These elements form the backbone of an efficient packaging line. Hipermak solutions are designed by placing the unique nature of gummy candies at the center of every detail.

Speed and Capacity: Not Faster, but Smarter

A common question gummy candy manufacturers ask is:

“Demand is increasing, but how long can we sustain this pace?”

Simply increasing machine speed is rarely the right solution. On the contrary, uncontrolled speed increases may lead to:

-

A decline in packaging quality

-

Weight inconsistencies

-

Unexpected downtime

This is exactly where one of our high-speed solutions, the CITIUS300 TW, comes into play. Developed specifically for confectionery and gummy candy applications, this machine can reach speeds of up to 600 PPM, while maintaining stability and consistent quality. As a result, manufacturers can manage capacity growth without turning it into a stressful process.

Choosing the Right Package Type: Performance Matters as Much as Appearance

Packaging selection in gummy candy production directly affects both production efficiency and consumer perception. The most commonly used packaging formats include:

-

Pillow packs

-

Doypacks

-

Stick packs

However, aesthetics alone are not enough. The selected packaging format must:

-

Be compatible with target production speeds

-

Provide reliable sealing

-

Support shelf life

With their flexible designs, Hipermak packaging machines allow manufacturers to adapt to different packaging formats, giving them greater freedom in the market.

Weight Accuracy and Waste Control

Even small weight deviations in the confectionery industry can turn into significant costs over time. This becomes even more critical for high-volume products like gummy candies.

With the right packaging line:

-

Weight consistency is maintained

-

Waste rates are reduced

-

Unit costs are kept under control

At Hipermak, our goal is to deliver stable and predictable results, even at high speeds.

Hygiene and Food Safety: The Foundation of Trust

In gummy candy packaging, hygiene is not just a regulatory requirement, it is the foundation of brand trust. That is why:

-

Easy-to-clean designs

-

Food-contact-safe materials

-

Fast maintenance and cleaning capabilities

must be prioritized. Hipermak machines are designed to make food safety a natural part of the production process.

Gummy Candy Packaging Is the Key to Sustainable Growth

Gummy candy packaging is a process that requires speed, precision, and flexibility to be managed simultaneously. With the right solutions:

-

Production capacity can be increased safely

-

Quality standards are maintained

-

Operational risks are reduced

According to Hipermak’s vision in confectionery packaging machinery manufacturing, packaging machines should support not only today’s needs but also tomorrow’s growth.

Investing in the right technology at the right time, with high-speed, reliable, and gummy-specific optimized solutions, provides manufacturers with a true long-term competitive advantage. For more information, feel free to contact us!