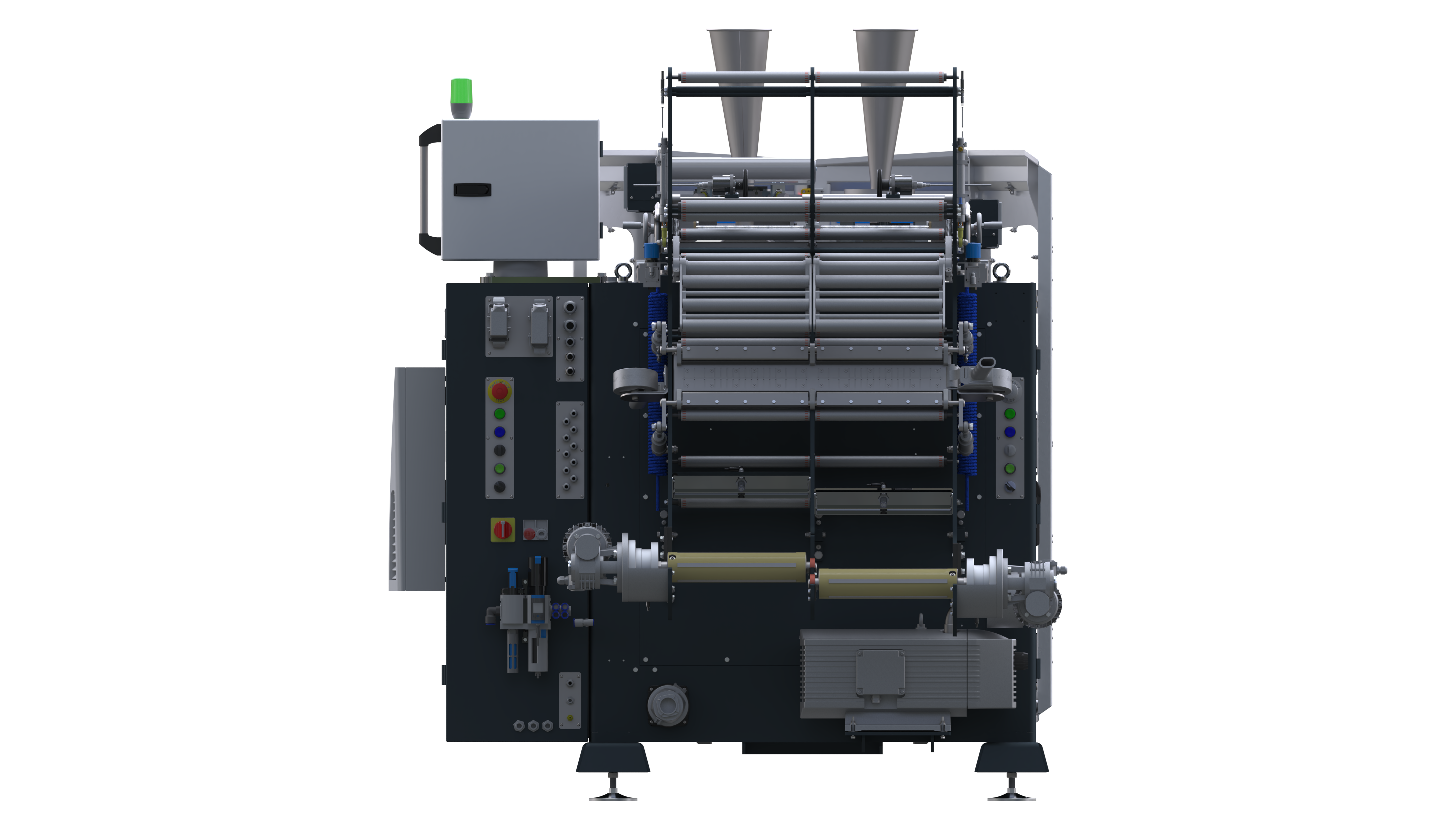

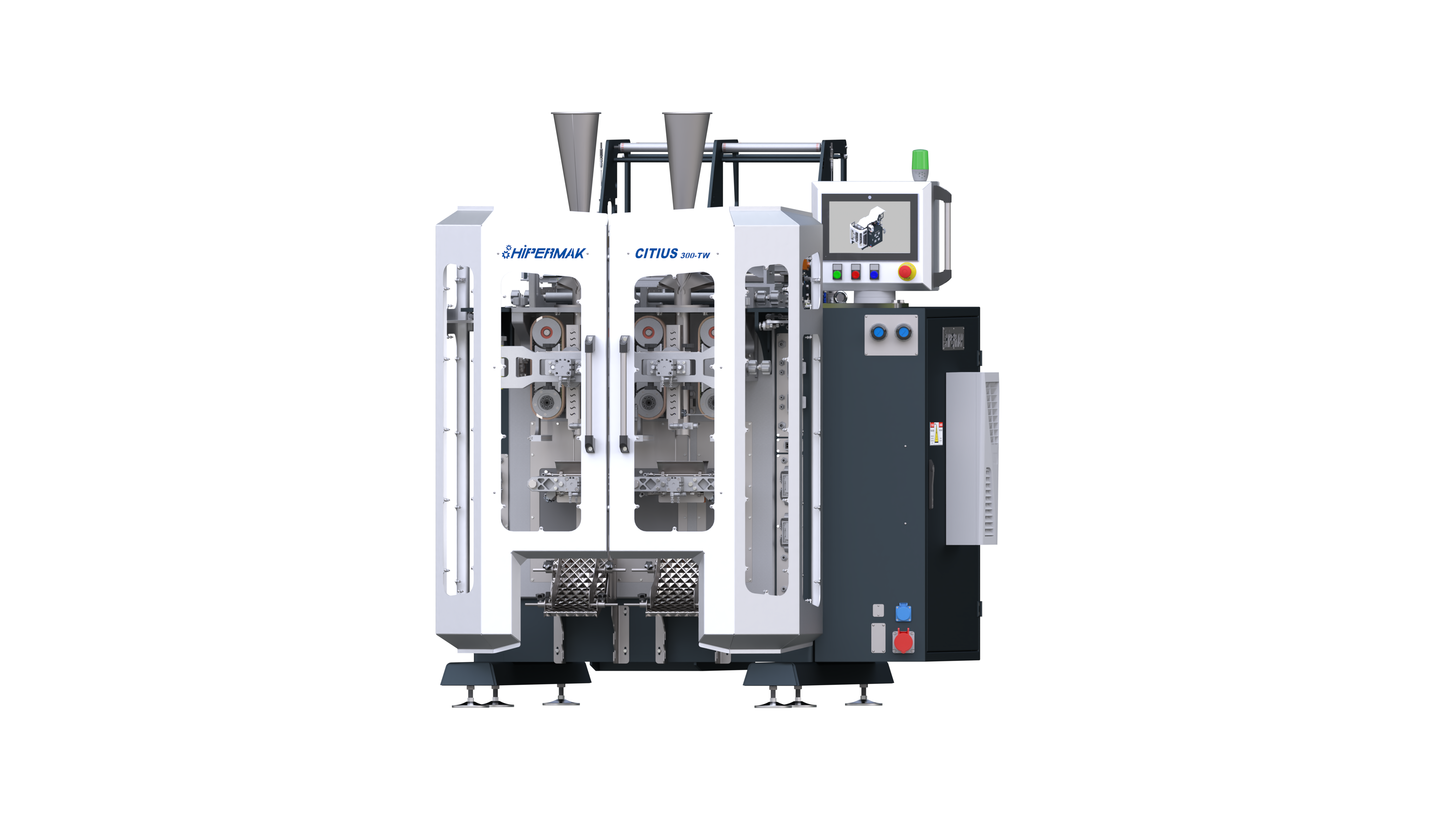

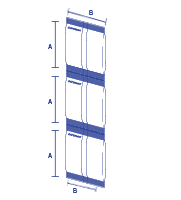

CITIUS300_TWINTUBE

MAXIMUM BAG/MINUTE: 500 PCS

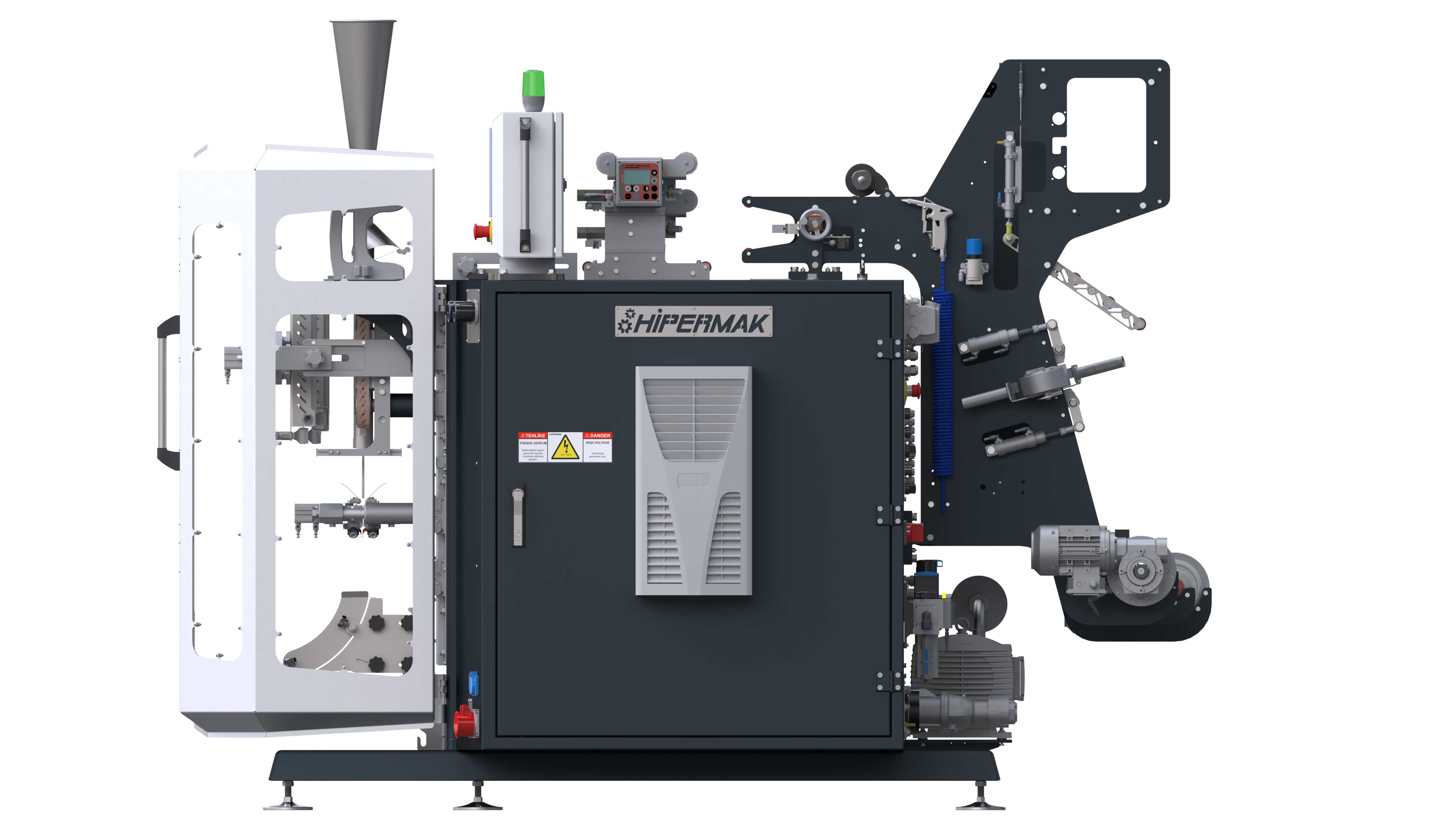

With its heavy body design that absorbs vibrations and a motion control system capable of reaching high speeds, our vertical packaging machine ensures maximum performance in continuous production. The vacuum film pulling system and ultrasonic sensor-based high-precision film centering guarantee smooth packaging with minimum waste.

A programmable automatic lubrication system and a three-stage electrostatic powder-coated body provide long-lasting durability and minimal maintenance requirements. The machine can operate with or without a photocell and is equipped with a 10’’ touch control screen, offering an intuitive user interface supported by clear graphics for seamless operation.

Thanks to PID temperature control, modular design for easy access to every part, and a hygienic structure that allows effortless cleaning, the system delivers consistent quality and reliability. Remote service support via standard Ethernet connection enables quick troubleshooting, while the jaw system detecting product jams ensures maximum efficiency. In addition, the ultrasonic coil diameter measurement and warning system, combined with the film splice detection sensor, further reduce packaging waste and optimize overall performance.

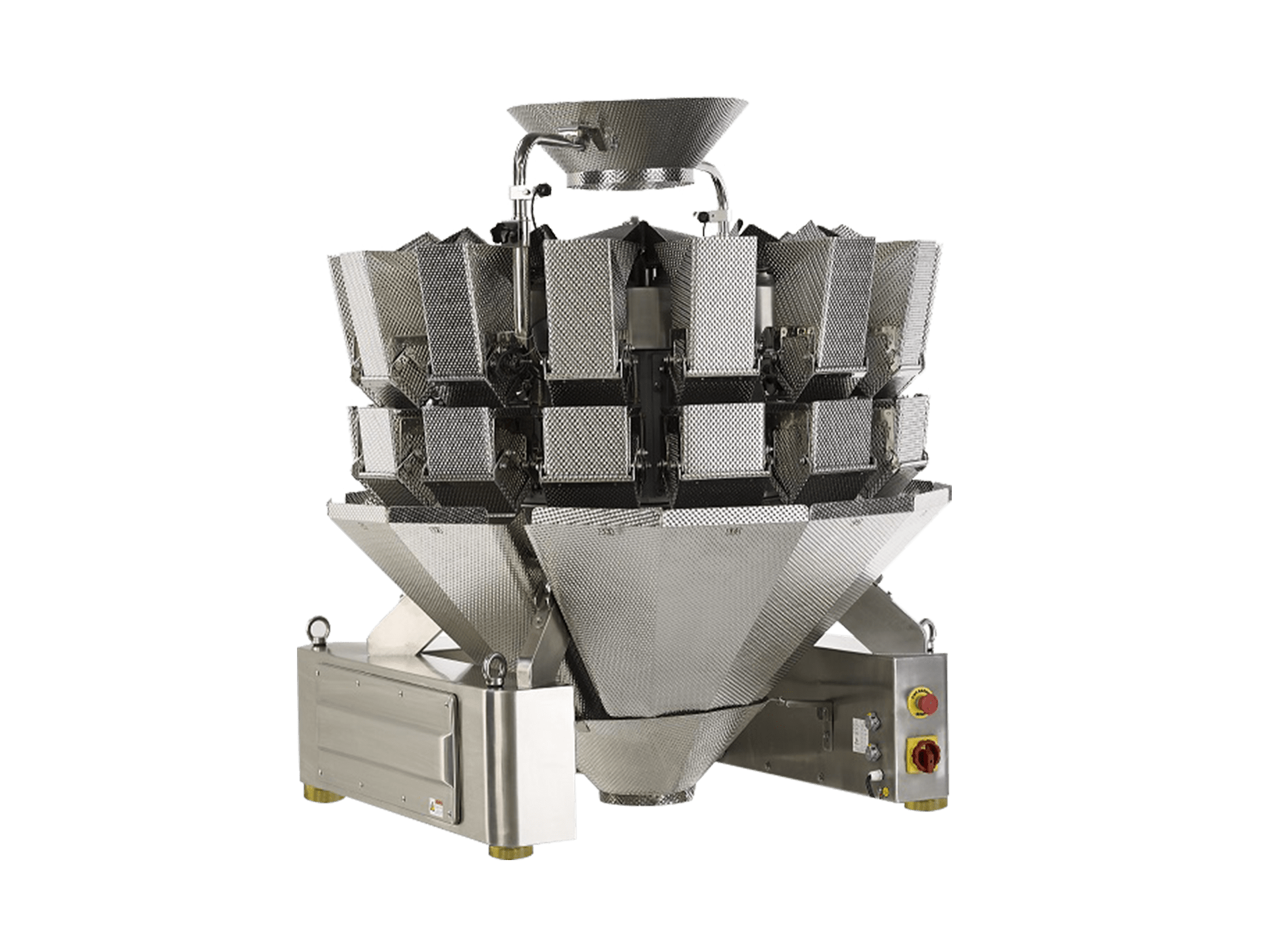

| Capacity: Max. 500 Pack / Min (Varies depending on product, package type and weight.) | |||||||

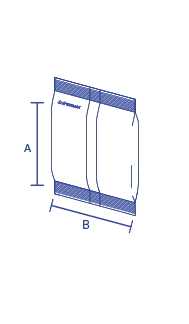

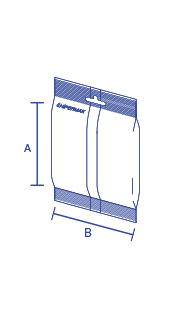

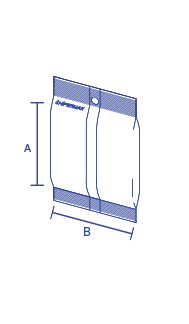

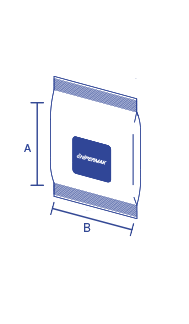

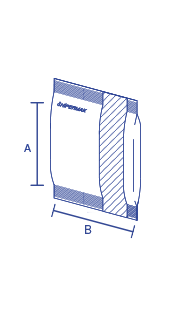

| Pack Dimensions: Yükseklik (80 mm – 230 mm) x En (45 mm – 140 mm) | Energy Consumption: 22 kW | ||||||

| Air Consumption: 6 – 8 Bar (100 Litre/Dk) | Sound level: DB < 70 | ||||||

| Max Reel Diameter: 300 mm | Servo Motor: Allen Bradley (USA) | ||||||

| Appx. Machine Weigth: 2400 kg | Sensor: Sick (Germany) | ||||||

| Voltage: 380V – 3 Faz – 50 Hz | Touch Screen: Allen Bradley (USA) | ||||||

| Voltage Range: ± 5 % | Electrical Parts: Schneider (Germany) | ||||||

| Edge Control: Microsonic (Germany) | Pneumatic Parts: Festo (Germany) | ||||||