CITIUS450_QA

MAXIMUM BAG/MINUTE: 250 PCS

Continous Motion Quadro Packaging Machine

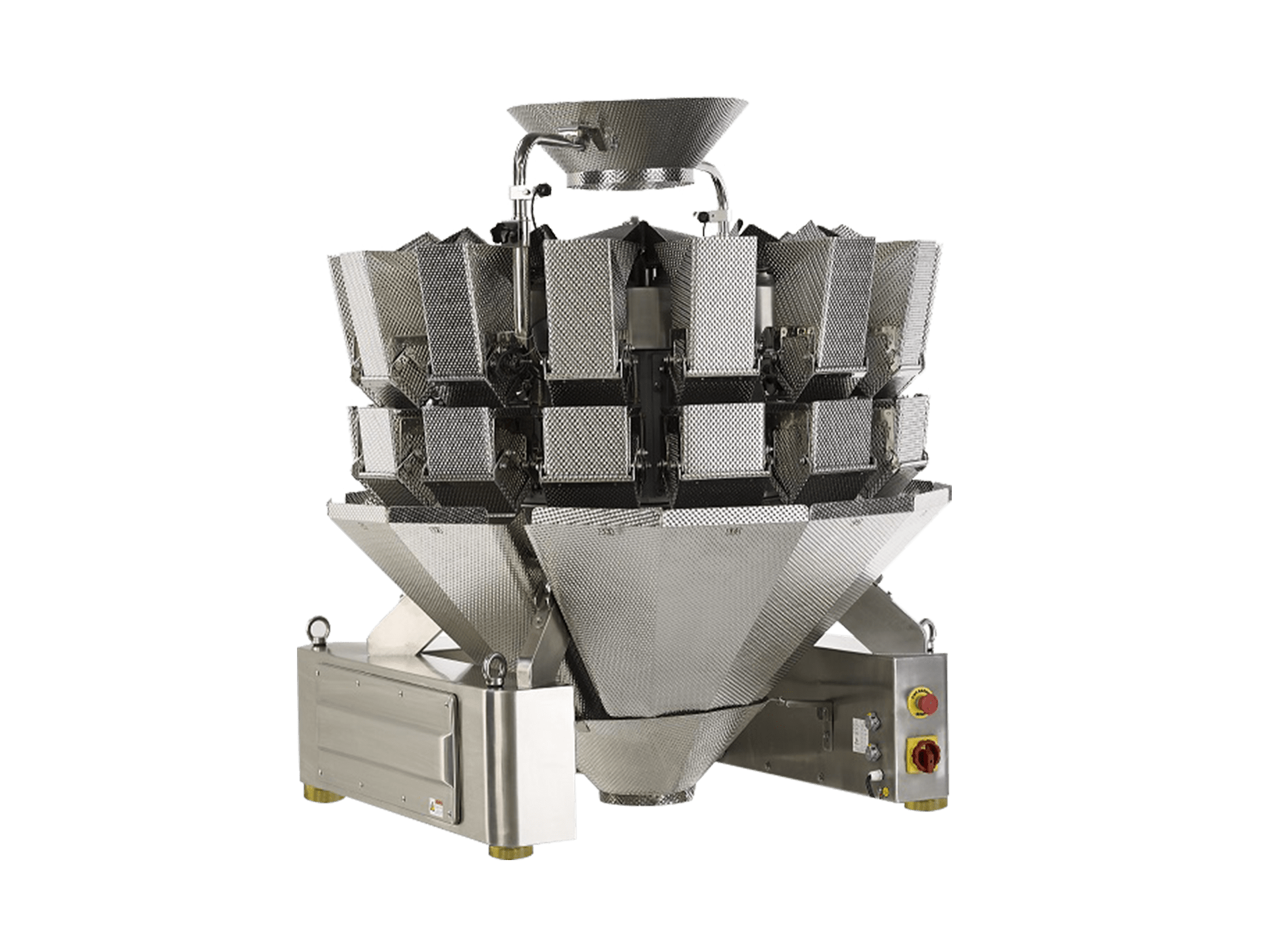

Our Citius450_QA VFFS Flexible Packaging Machine, working with the Continous-Motion system, can work 24/7 with the highest possible packaging capacity depending on the product and weight.

Our precision filling units, which work in harmony with our Citius450_QA series VFFS QuadroPackaging Machine, provide the user with the highest efficiency packaging with low packaging and low product waste.

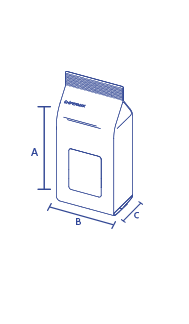

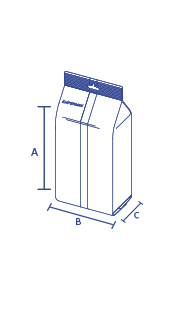

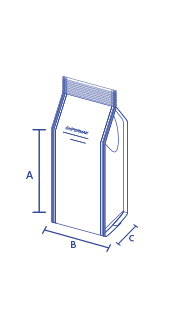

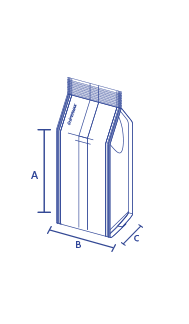

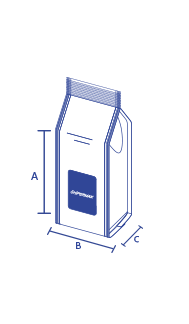

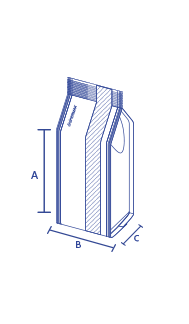

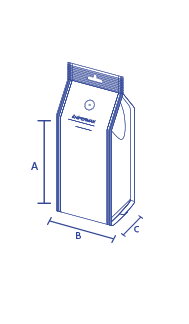

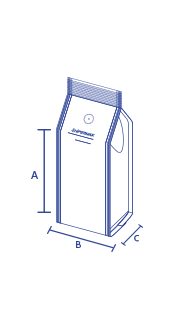

In our Citius450_QA Series Vertical Packaging Machine, which offers a wide weight range and the opportunity to work with a wide variety of package types in a single machine, standard servo motor application in the Traveling Jaw and film puller system, Vacuum Timing Belts, 10” color touch screen where all the control of the machine is made, film coil Many features such as level sensor, error and alarm control system, very-low noise level are offered as standard.