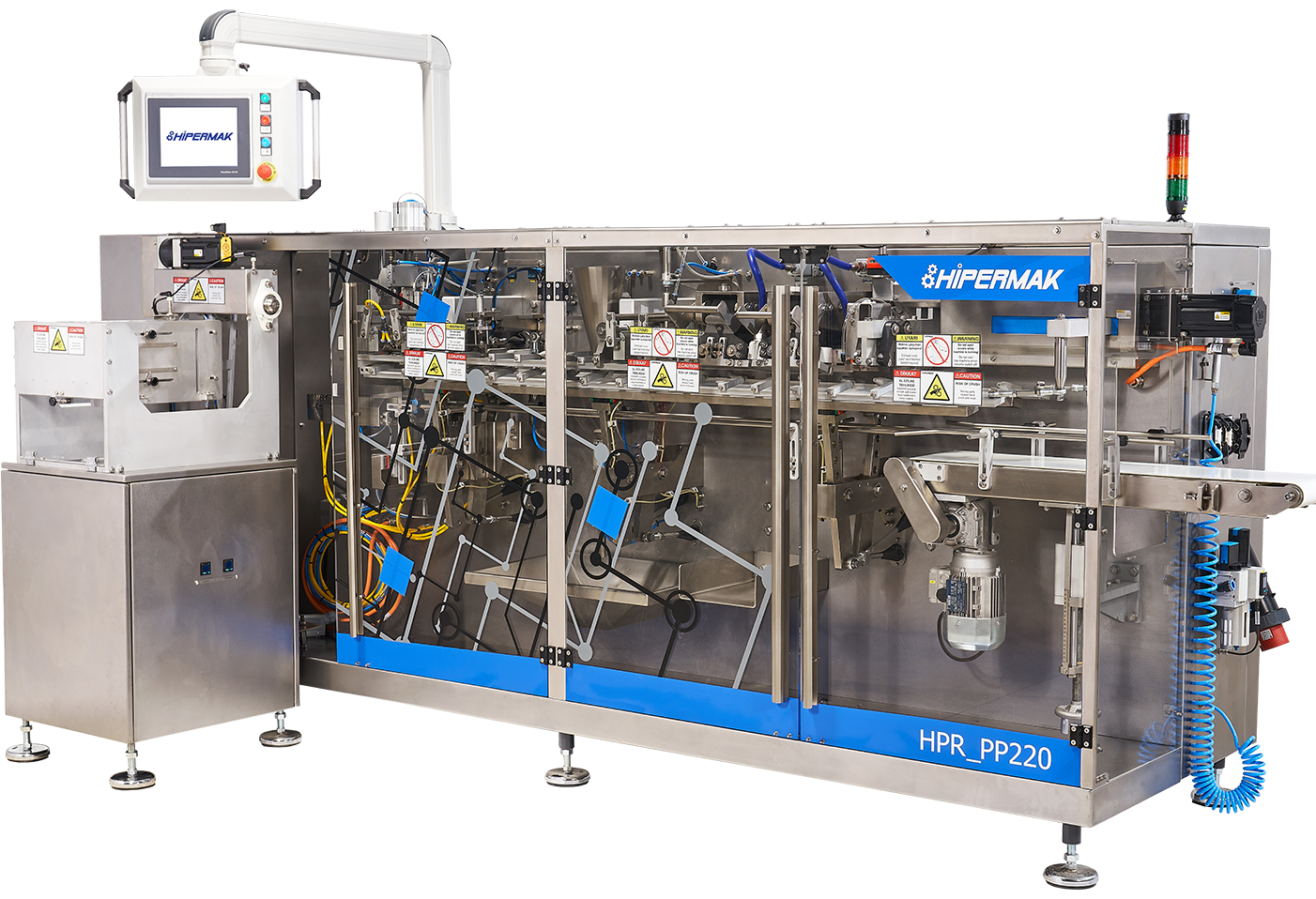

FACILIS220 – Pre-Made Pouch Packagıng Machıne

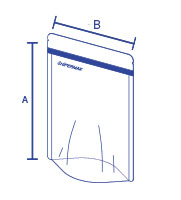

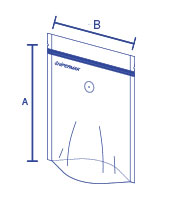

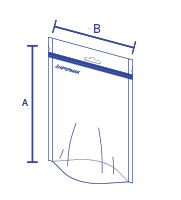

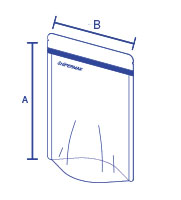

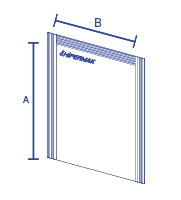

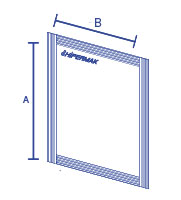

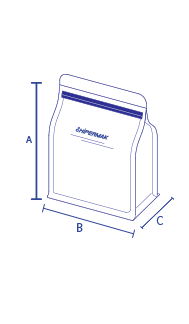

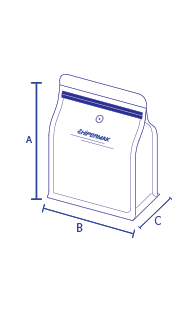

MINIMUM BAG SIZE: 85X140MM

MAXIMUM BAG SIZE 210X280MM

MAXIM BAG / MIN: 60 PCS

MAXIMUM BAG SIZE 210X280MM

MAXIM BAG / MIN: 60 PCS

Our Facilis220 model Horizontal Type Pre-Pouch Doypack Packaging Machine, which offers flexible production, allows uninterrupted packaging with its fast package change feature that it offers to businesses with different sizes, designs and package types.

The Zip opening station, which is specially manufactured for zipped packages, enables the use of Zipless packages as well as Zip packages on the same machine.

Remote Access

Centralized Lubrication

Temperature Control with PID

Machine Error / Alarm History

Zipper Openning System with Vacuum

Maximum access for clean and maintenance

Dynamic Touch Screen (360° Around Machine – 360° Own Axis)

Production Control with Bag Counter and Target Bag Quantity

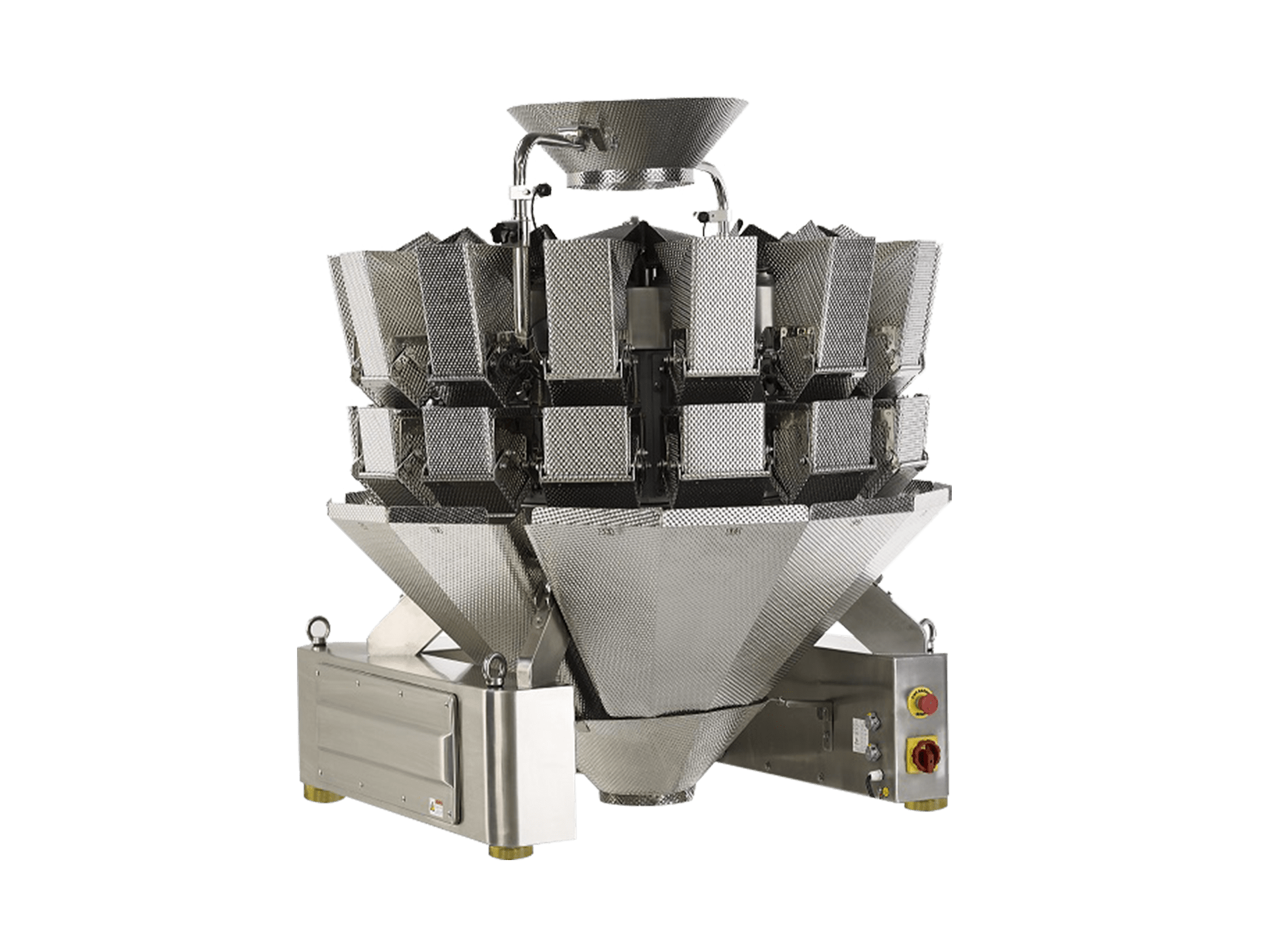

Highly suitable for all kind of Filling Units (Weigher, Auger, Volumetric)

Fast, Precise and Stable Packaging Process with Motion Control Servo Technology

The main body of the machine is Epoxy painted steel and covered with AISI 304 CR-NI

| Capacity | 60 Pcs / Min Maximum | Servo Motor | Allen Bradley ( USA ) |

| Bag Dimensions | H: 140mm – 280mm – W: 85mm – 210mm | Touch Screen | Allen Bradley ( USA ) |

| Voltage | 380V/415V – 3 Faz – 50Hz/60 Hz | Pneumatic Equip. | Festo ( German ) |

| Power | 4,5 kW | Electronic Parts | Schneider ( German ) |

| Voltage Range | ± 5 % | Sensor | Sick ( German ) |

| Air Requirement | 6 – 8 Bar ( 100 Liter / Min ) | Bearing | SKF ( Sweden ) |

| Fitting Parts | DIN 933/931 A2 AISI304 AA-70 | AC Motor | Bonfiglioli ( Italy ) |

| Weight | 2000 KG | Reductor | Bonfiglioli ( Italy ) |

| Noise Level | DB < 70 | Edge Control | Microsonic ( German ) |

| Color | 7016 / 7035 |

Nitrogen Gas Flushing System

Programmable Centralized Lubrication

Feeding Elevator

Feeding Helezone

Rotary Table

Check Weigher

Metal Dedector

X-Ray Machine

Inkjet Printer