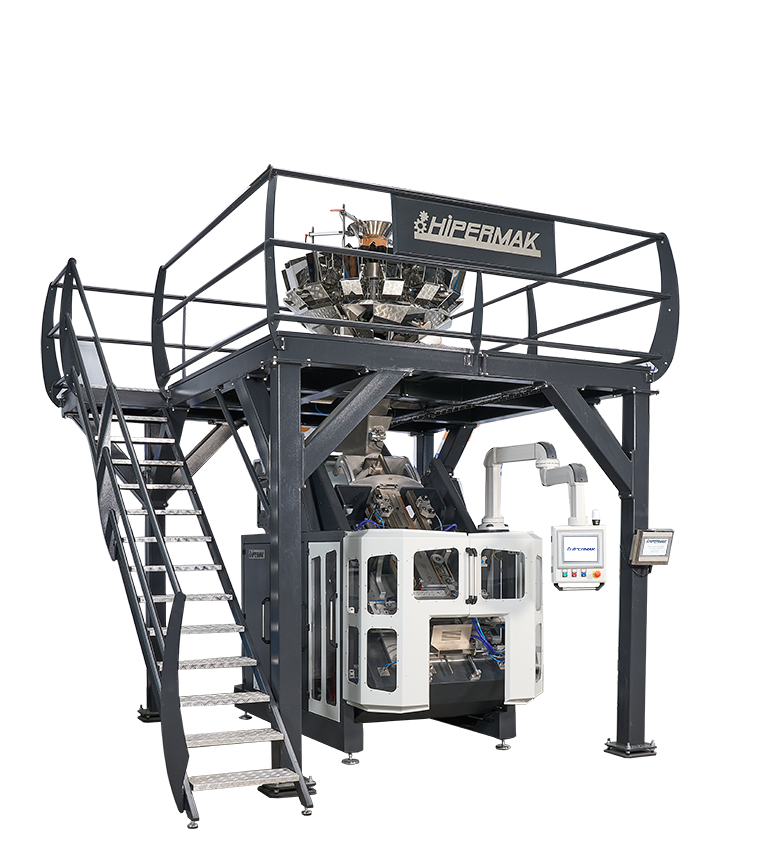

CORDIA SF QA

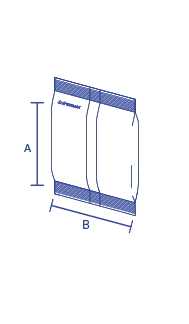

MAXIMUM BAG WIDTH: 290MM

MAXIMUM BAG/MINUTE: 45 PCS

MAXIMUM BAG/MINUTE: 45 PCS

Our Cordia SF QA Inclined Packaging Machine, equipped with Motion Control technology, are designed to meet the needs of both food and non-food industries and are specially manufactured for fragile products such as biscuits and crackers.

The Cordia SF QA Inclined Packaging Machine offers the ability to handle a wide weight range and various packaging types on a single machine, with standard features such as remote access, automatic film feeding, central lubrication system, film centering, and automatic edge control system.

Equipped with a nitrogen gas injection system and valve assembly equipment, the Cordia SF QA Inclined Packaging Machine ensures that the products maintain their aroma, flavor, and freshness for an extended period, delivering them to consumers with the same quality as the first day.

Precise packaging for fragile and delicate products requiring gentle handling

Vibration-absorbing heavy body design

Fast, precise, and stable operation with motion control servo technology

Electrostatic powder-coated body applied in 3 stages

Adjustable angle up to 45° depending on product type

Error and alarm monitoring system

Capability to operate with or without a photocell

Reporting of production quality and operator performance

Stable film tension control with a pressure-adjusted balance arm

PID system temperature control

High-precision edge control and film centering system with an ultrasonic sensor

10’’ touchscreen control panel

Ease of cleaning and maintenance with hygienic design

Easy access to all parts of the machine thanks to modular design

Programmable central lubrication system

Remote service support with a standard Ethernet connection for quick intervention in case of malfunctions.

Capacity: Max. 45 packs/min (varies depending on product, package type, and weight)

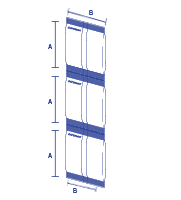

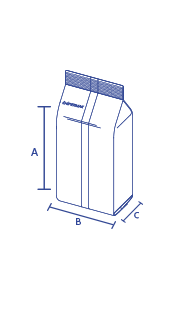

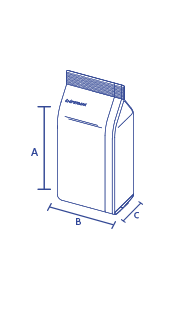

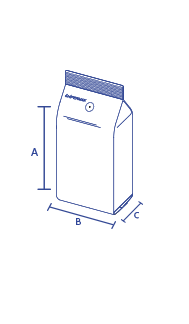

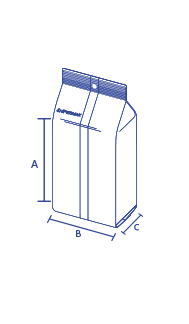

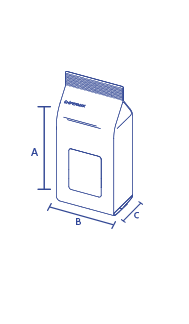

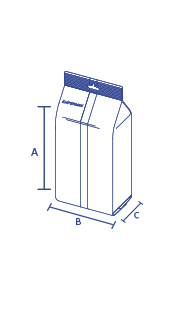

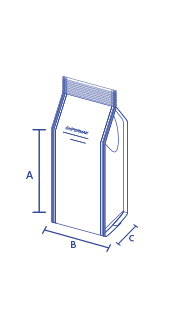

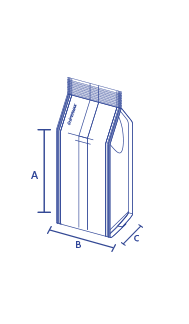

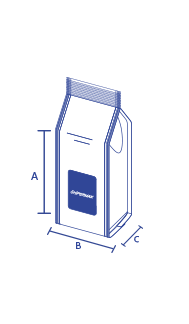

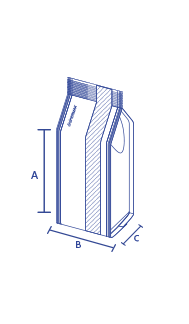

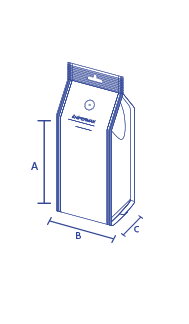

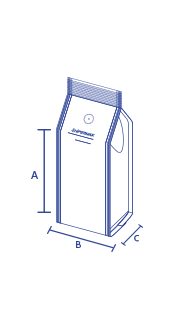

Package Dimensions: Height (120 mm – 500 mm) x Width (600 mm – 225 mm)

Power Requirement: 11.5 kW

Air Requirement: 6 – 8 Bar (100 Liters/min)

Noise Level: < 70 dB

Max. Reel Width: 620 mm

Servo Motor: Allen Bradley (USA)

Approximate Machine Weight: 2250 kg

Sensor: Sick (Germany)

Voltage: 380V – 3 Phase – 50 Hz

Touchscreen: Allen Bradley (USA)

Voltage Range: ± 5%

Electrical Components: Schneider (Germany)

Edge Control: Microsonic (Germany)

Pneumatic Components: Festo (Germany)

Dust Extraction System

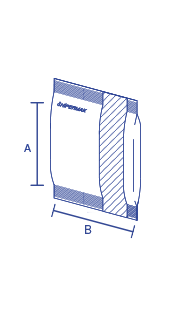

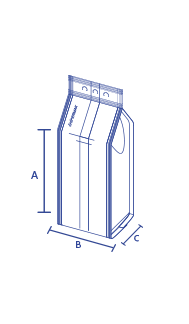

Gusseted Package Attachment

Gas Injection System

Valve Assembly and Feeding System

Label Applicator

Gift Card System

Advertisement Banner/Promotional Tape System

Online Oxygen Measurement System

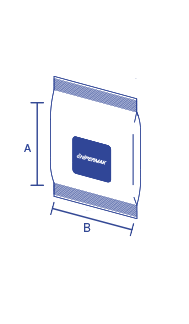

Horizontal Jaw for Polyethylene Packaging

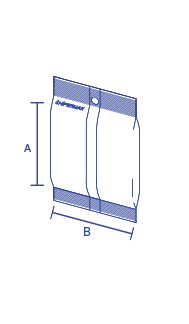

Horizontal Jaw with Carrying Hole

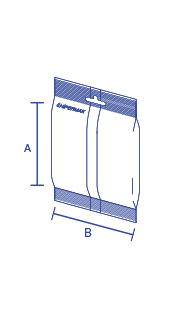

Euro Slot Jaw System

Vacuum Film Pulling System

Antistatic System

Panel Air Conditioning

Stainless Steel Design

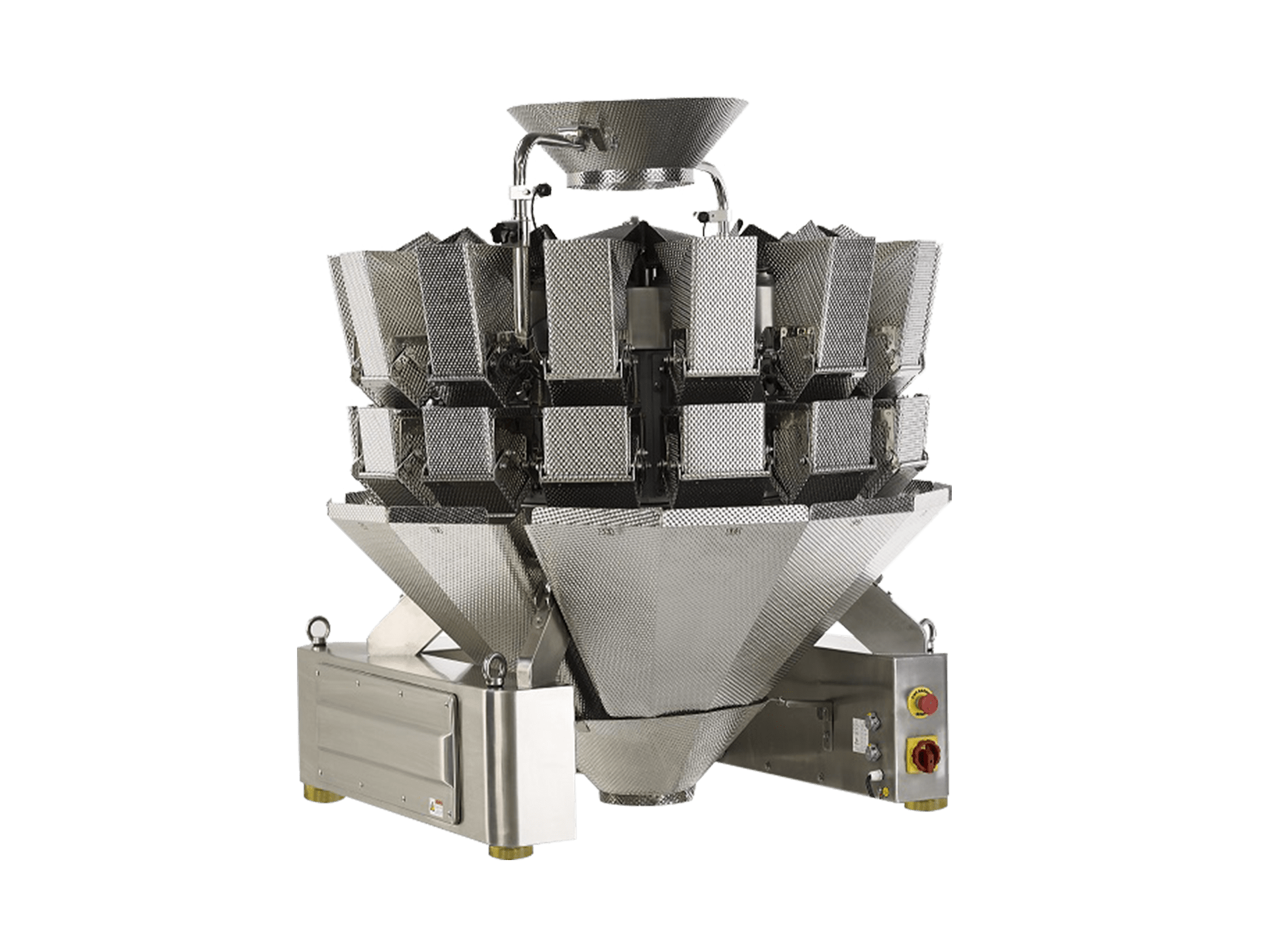

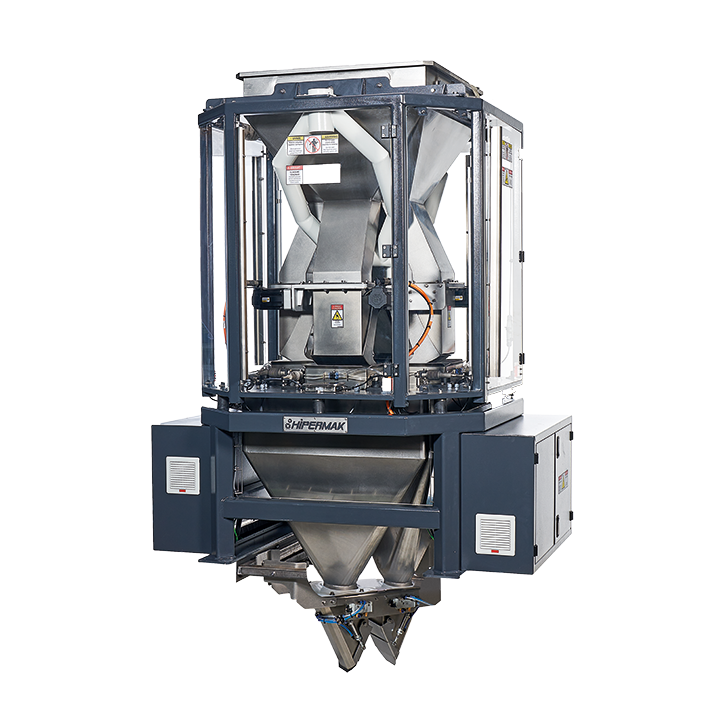

Granular Product Feeding System

Powder Product Feeding System

Thermal Transfer Printer

Rotary Table

Check Weigher

Metal Detector

X-Ray Inspection Device