FIXUS620_QA

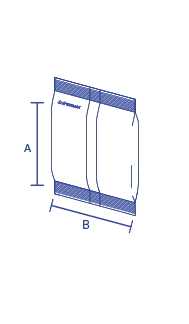

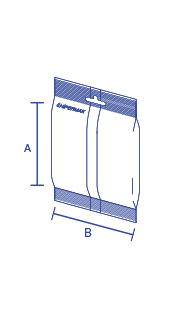

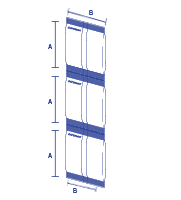

MAXIMUM BAG WIDTH: 450MM

MAXIMUM BAG/MINUTE: 60 PCS

MAXIMUM BAG/MINUTE: 60 PCS

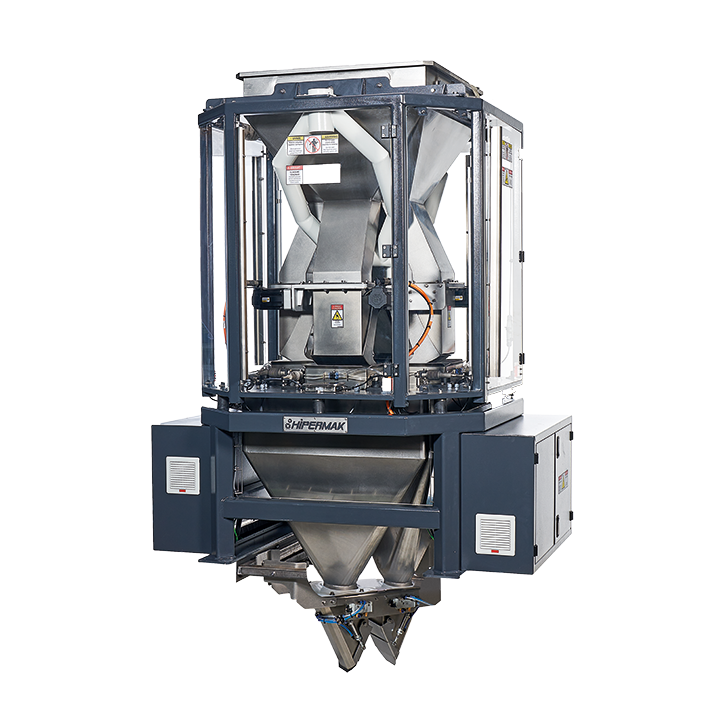

Our Basic Series Fixus620 Quadro series Vertical Packaging Machines with Motion Control technology is suitable for many sectors, including food and non-food.

In our Fixus620 Series Quadro Vertical Packaging Machine, which operates seamlessly with the combination of mechanical and servo motor technology, several features are offered as standard, such as P.I.D temperature control system, stable film tension control with pressure-adjustable balance arm, and the ability to operate with or without a photoelectric sensor.

HPR_BS5000_QA works with perfect match of mechanic and servo motor technology,

Work FAST, SENSITIVE and STABLE with servo motor technology,

Production Control with the Targeted Package Quantity

Electrostatic Powder Coated Machine Body

Able to work with or without Photocell

P.I.D Temperature Control System

Alarm Control System

AISI 304 CR-NI forming tube

Capacity: Max 50 Pieces / Minute (Vary on product, bag type and grammage)

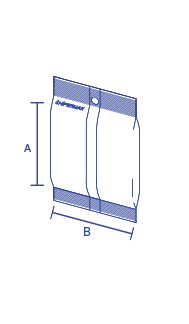

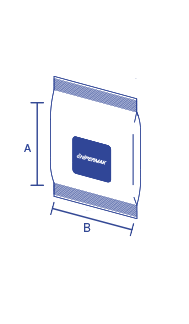

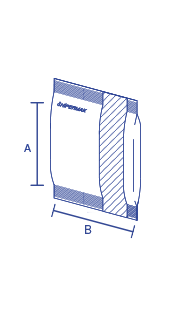

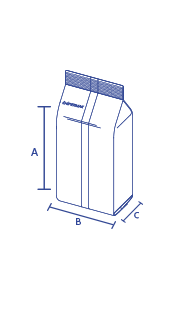

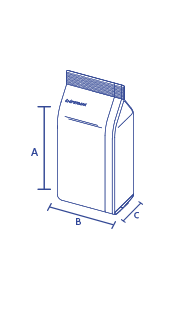

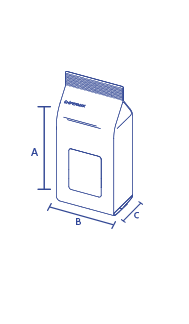

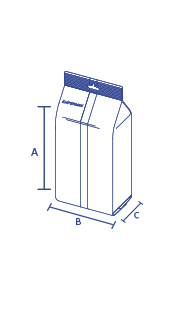

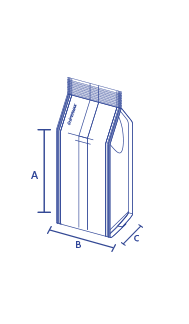

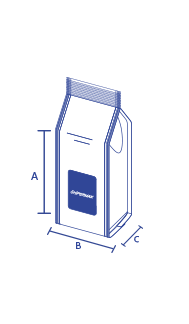

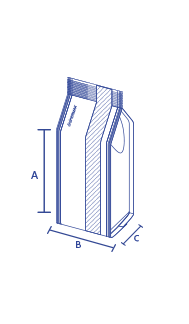

Package Dimentions: Height (60mm – 450mm) x Width (60mm – 300mm)

Air Requirement: 6 – 8 Bar (100 Liter / Min)

Bobbin Outside Ø: 400 mm

Bobbin Inside Ø: 76 mm

Max Bobbin Width: 620 mm

Weight: 1000 Kg

Voltage: 380V – 3 Faz – 50 Hz

Voltage Range: ± 5 %

Power: 4,5 kW

Loudness Level: DB < 70

Servo Motor: Schneider (Germany)

Touch Screen: Schneider (Germany)

Sensor: Sick (Germany)

Electrical Parts: Schneider (Germany)

Pneumatical Parts: SMC (Japan)

AC Motor: Gamak (TR)

Reductor: Yılmaz (TR)

Colour Code: 7016 / 7035

Bearing: SKF (Sweden)

Fitting Parts: DIN 933 A2 AISI304 AA-70 / DIN 931 A2 AISI304 AA-70